- Youtube

Innovative, efficient, and reliable. Our cutting-edge crane solutions integrate advanced technology for optimal performance, safety, and precision.

ABEGT Brakes Solution leads the industry in providing state-of-the-art crane brake solutions, dedicated to enhancing operational safety and efficiency. With extensive expertise in the field, we specialize in delivering superior brake systems tailored to diverse crane applications. Our team of skilled engineers and technicians is committed to offering top-of-the-line brake solutions for various crane types, including single-girder, double-girder, and gantry cranes.

Whether you require standard brake systems or custom-engineered solutions, ABEGT Brakes Solution offers a comprehensive range of products built to the highest standards of quality and reliability. We understand the critical importance of brake performance in heavy lifting operations, and our products are designed to not only meet but exceed industry standards.

Our unwavering dedication to optimal brake performance and longevity in demanding environments ensures that our brake systems enhance the safety and efficiency of your crane operations. When you partner with ABEGT for your brake needs, you benefit from our industry-leading expertise, cutting-edge technology, and steadfast commitment to safety, taking your crane operations to new levels of excellence.

We offer a comprehensive array of crane brakes components designed to meet diverse needs in overhead crane construction. Our products cater to a wide range of crane types and lifting requirements, Our team of experts is adept at assessing precise specifications to determine the most suitable crane brake capacity.

The hydraulic brakes marketed by ABEGT are meticulously crafted to deliver a formidable braking force of up to 600,000 Newtons, tailored precisely to meet the operational requirements of overseeing heavy machinery and handling significant loads with accuracy and dependability.

The Abegt’s range of pneumatic brakes are operated using dry and compressed air at pressures up to 7 bar. Equipped with a control valve, these brakes can be operated manually or via an electric signal, offering a braking force of up to 25,000 N.

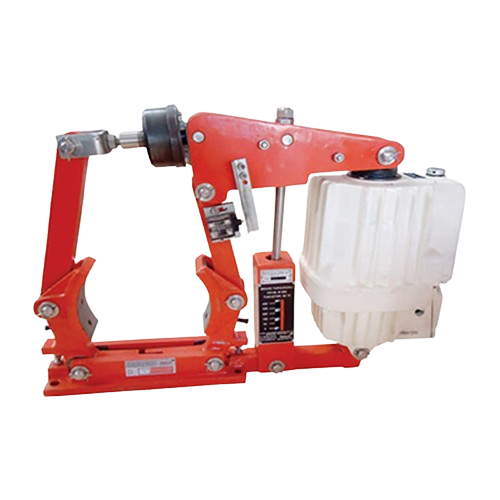

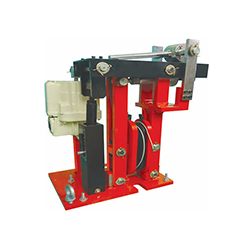

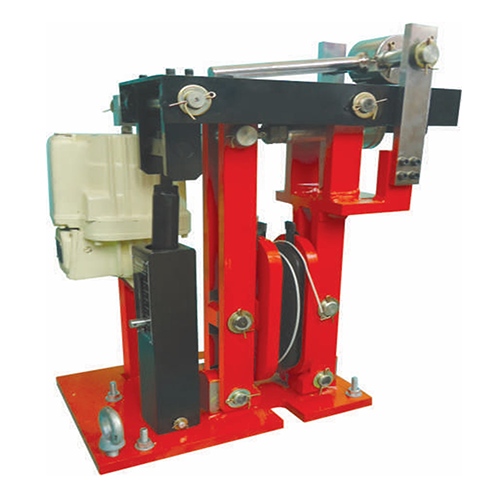

The Abegt’s Electro-Hydraulic Thruster-driven Drum Brake offers a versatile and durable solution tailored for applications in Cranes, Conveyors, and Material Handling Equipment. Featuring drum sizes spanning from 100mm to 760mm and a torque capacity of up to 9600NM, these brakes are meticulously crafted to fulfill a diverse array of industrial needs.

These brakes are not just functional; they are designed with the end-user in mind, offering features that ensure ease of use, safety, and reliability. Whether it’s adjusting the braking force to match specific requirements or ensuring maintenance is straightforward and minimal, Kateel’s Electro-Hydraulic Thruster-operated Drum Brakes are an ideal choice for heavy-duty industrial applications.

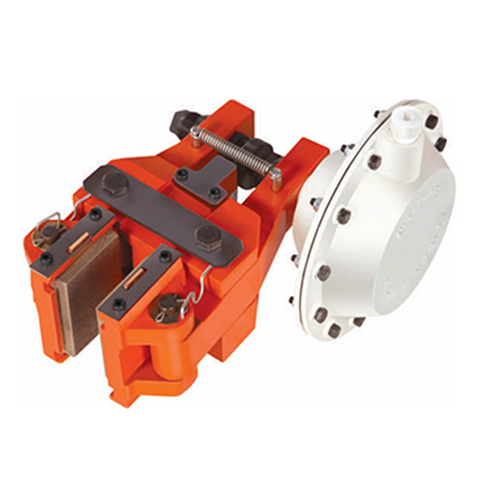

Electro-Hydraulic Thruster Disc Brake showcases fail-safe braking technology. When the motor is activated, it creates hydraulic pressure in the thruster, lifting the piston to release the brake. Conversely, if there’s a power outage, the hydraulic pressure decreases, causing the piston to lower and the brake arm to push the pad against the disc using spring force, engaging the brake. This system can produce a torque of up to 25,000 NM and is compatible with brake discs up to 1200mm in diameter.

The Electro-Hydraulic Thruster Disc Brake by Abegt is meticulously designed to adhere to stringent safety and performance criteria crucial for demanding industrial uses, especially in port handling and conveyor systems.

The Abegt Rail Clamps serve as vital parking brakes for Gantry Cranes and Ship Unloaders in coastal regions. Comprising two primary links, one end of these clamps connects to a hydraulic actuator, while the other end features brake pads. These links are hinged and supported by an internal frame, connected to springs via additional links. An external frame affixed to the machinery, ensures stationary positioning by clamping the rails with spring force during parking.

To initiate movement, the rail clamp disengages through hydraulic cylinder activation. A floating connection between the internal and external frames accommodates misalignment during Gantry Crane and Ship Unloader movement. In the parked position, the clamp is designed to withstand separating forces from environmental factors such as wind or storms.

With a capacity of 130 KN, the Rail Clamp is engineered to handle the demanding conditions of its operational environment effectively.

The Abegt Rail Clamp is designed to ensure consistent stability, providing increased safety and reliability for Gantry Cranes and Ship Unloaders, especially in environments exposed to substantial external forces.

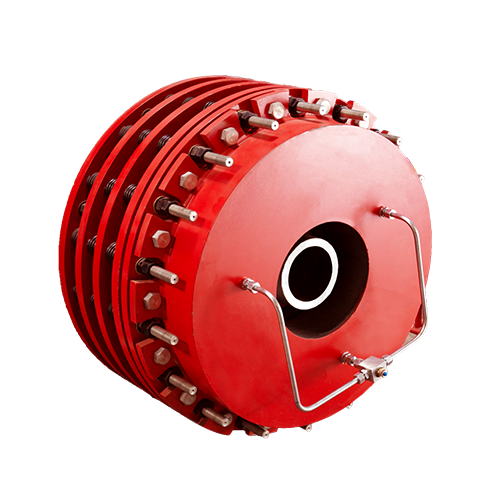

Abegt has designed a range of high-torque, spring-applied disc brakes specifically crafted for Surface Mining, Oilfield, and diverse heavy-duty industrial uses. These brakes are meticulously engineered to deliver dependable stopping and holding capabilities, particularly in urgent and safety-sensitive situations. With the ability to accommodate multiple discs, the standard brake models can achieve an impressive maximum static torque of 620,000 NM. A notable advantage of these brakes lies in their pneumatic release mechanism, which mitigates worries associated with brake oil contamination, hydraulic leaks, or the upkeep of high-pressure lines.

Abegt’s air-cooled disc brakes are a testament to innovative engineering, designed to meet the rigorous demands of heavy-duty industries, ensuring enhanced safety and performance reliability.

ABEGT Crane Solutions brings a wealth of experience, with team members possessing decades of hands-on involvement in the crane industry.

We stay at the forefront of technological advancements, integrating cutting-edge solutions into our overhead crane systems. This ensures that our clients benefit from the latest innovations for optimal performance.

Our expertise extends across various industries, including manufacturing, construction, logistics, and more. Whatever your specific needs for heavy lifting may be, ABEGT Crane Solutions offers superior overhead crane solutions tailored to your application.

From the initial consultation to installation and ongoing maintenance, our team of skilled engineers and technicians is dedicated to providing comprehensive support at every stage of the process.

Recognizing the unique requirements of each client, we pride ourselves on delivering customized solutions. Our approach ensures that your overhead crane system is precisely designed to meet your industry-specific demands.

ABEGT Crane Solutions prioritizes quality and safety in all aspects of our services. Our commitment to industry standards ensures that our overhead crane solutions not only meet but exceed safety regulations, providing a secure lifting environment.

Love to Hear from Our Customers